Production Equipment

Molding and Casting Equipment

Injection Molding Machines: High-precision machines for

producing plastic components with tight tolerances.

Die Casting Machines: Used for manufacturing metal parts

with high strength and durability.

Rotational Molding Machines: Ideal for creating large,

hollow parts such as ice bath tubs.

Metalworking Equipment

CNC Lathes and Milling Machines: For precision machining of

metal components.

Laser Cutting Machines: Used for cutting metal sheets with

high accuracy and minimal material waste.

Sheet Metal Press Brakes: For bending and forming metal

sheets into desired shapes.

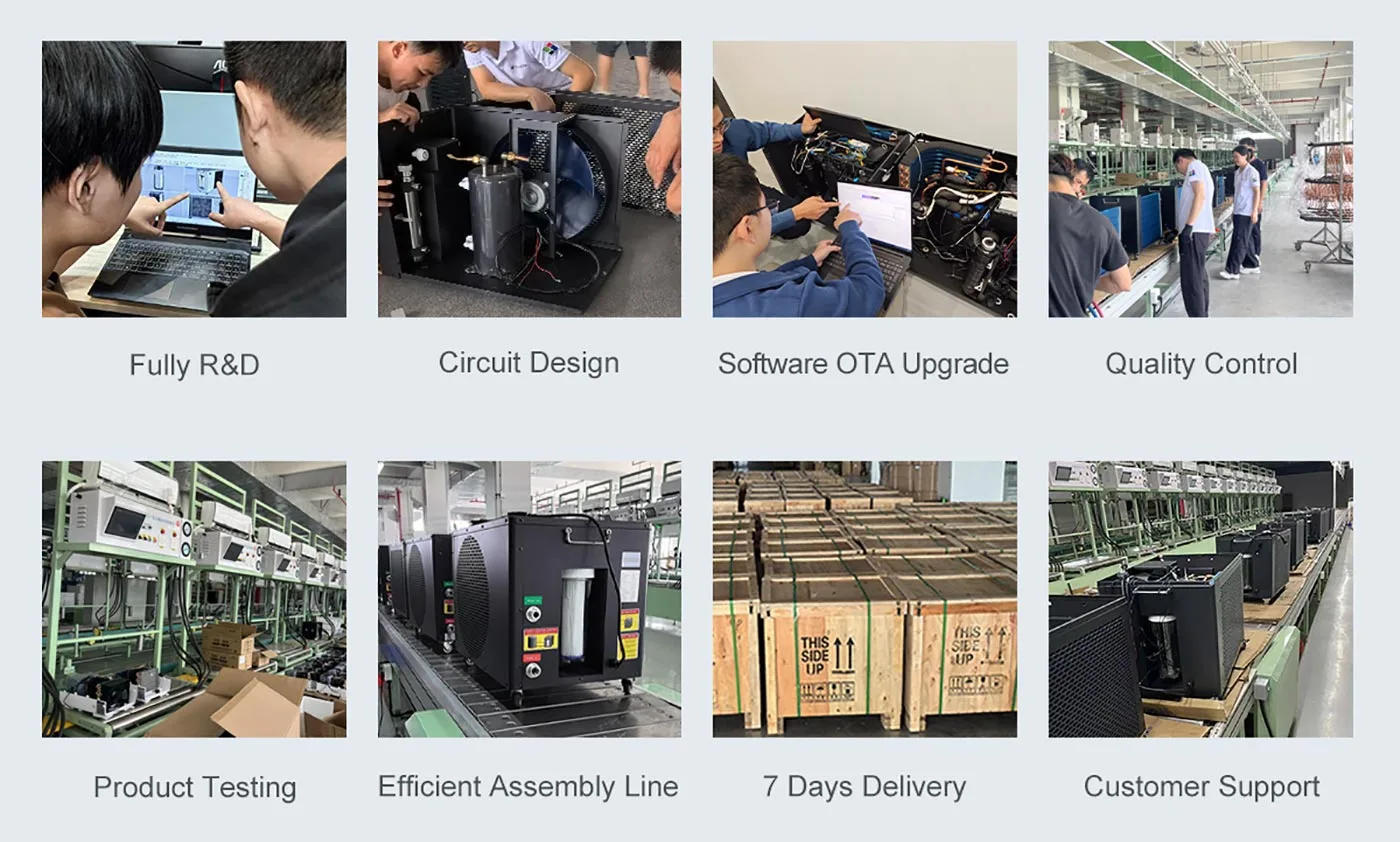

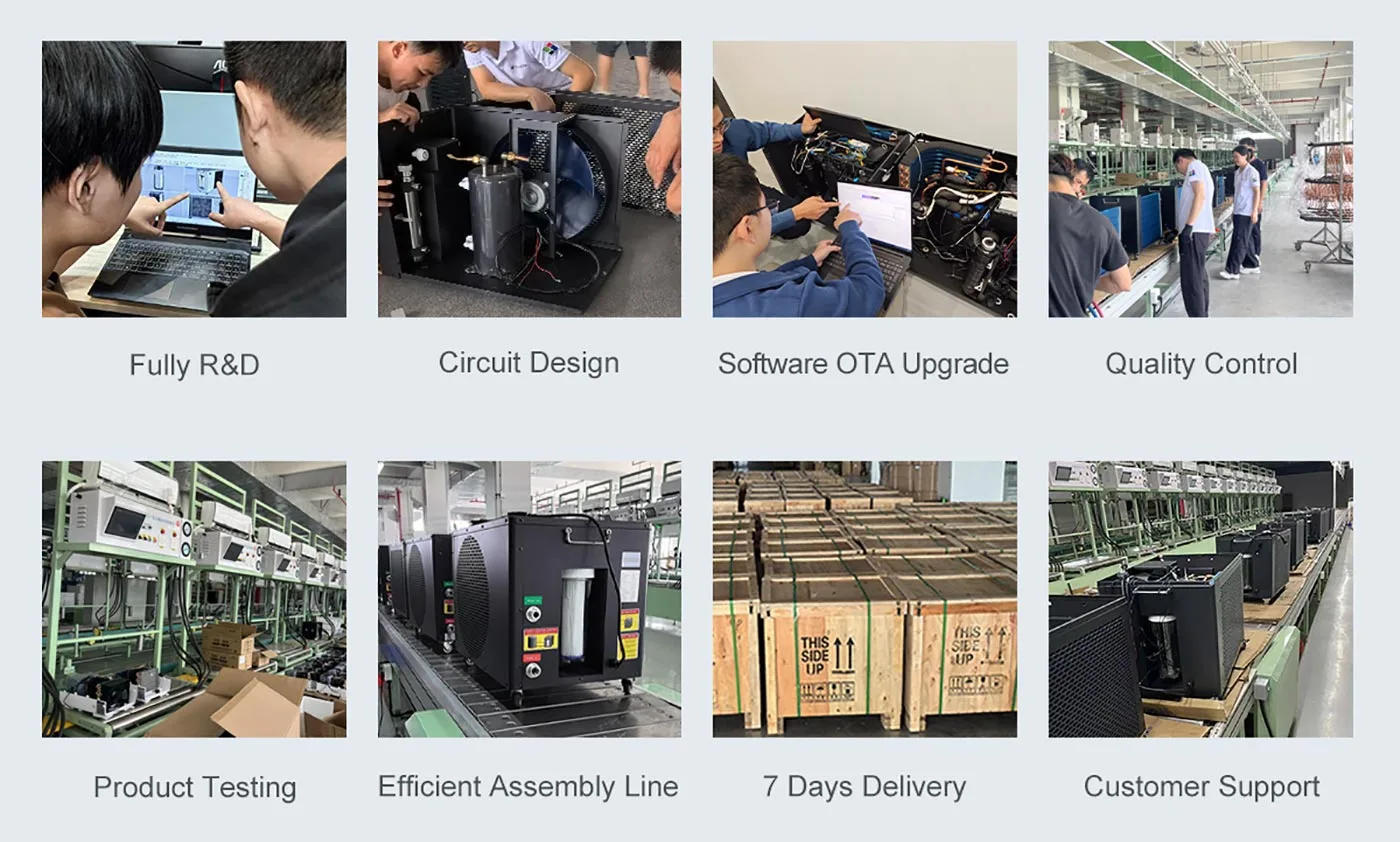

Welding and Assembly Equipment

Automated Welding Robots: Ensuring consistent and

high-quality welds for metal structures.

Spot Welding Machines: For joining metal components with

precision.

Assembly Lines: Equipped with ergonomic workstations and

conveyor systems for efficient assembly processes.

Quality Control and Testing Equipment

3D Coordinate Measuring Machines (CMM): For precise

measurement and inspection of parts.

Leak Detection Equipment: To ensure the watertight

integrity of ice bath machines.

Temperature and Pressure Testing Systems: To verify the

performance and safety of the ice bath systems under various conditions.

Finishing and Surface Treatment Equipment

Powder Coating Lines: For durable and corrosion-resistant

finishes on metal parts.

Electroplating and Anodizing Equipment: Used for surface

treatment to enhance the appearance and durability of components.

Paint Spray Booths: For applying high-quality, uniform

paint coatings.

Packaging and Logistics Equipment

Automated Packaging Machines: For efficient packaging of

finished products.

Forklifts and Pallet Racking Systems: For handling and

storage of raw materials and finished goods.

Logistics and Shipping Equipment: Including palletizers,

stretch wrappers, and loading docks.

Supporting Facilities

Quality Control Laboratories: Equipped with advanced

testing instruments for material analysis and product testing.

Research and Development Centers: Focused on continuous

improvement and innovation of our products.

Maintenance and Calibration Facilities: To ensure all

equipment is regularly serviced and calibrated for optimal performance.

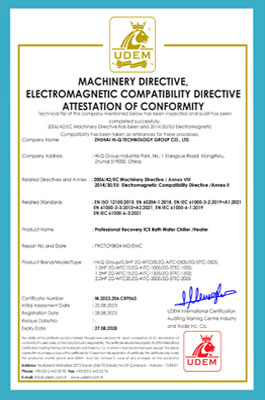

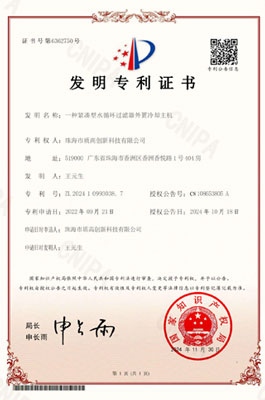

Our production facilities are designed to meet international standards, and

our commitment to quality is reflected in every aspect of our manufacturing

process. We are confident that our advanced equipment and experienced team

can deliver products that meet your highest expectations.

Why Choose Hi-Q Group